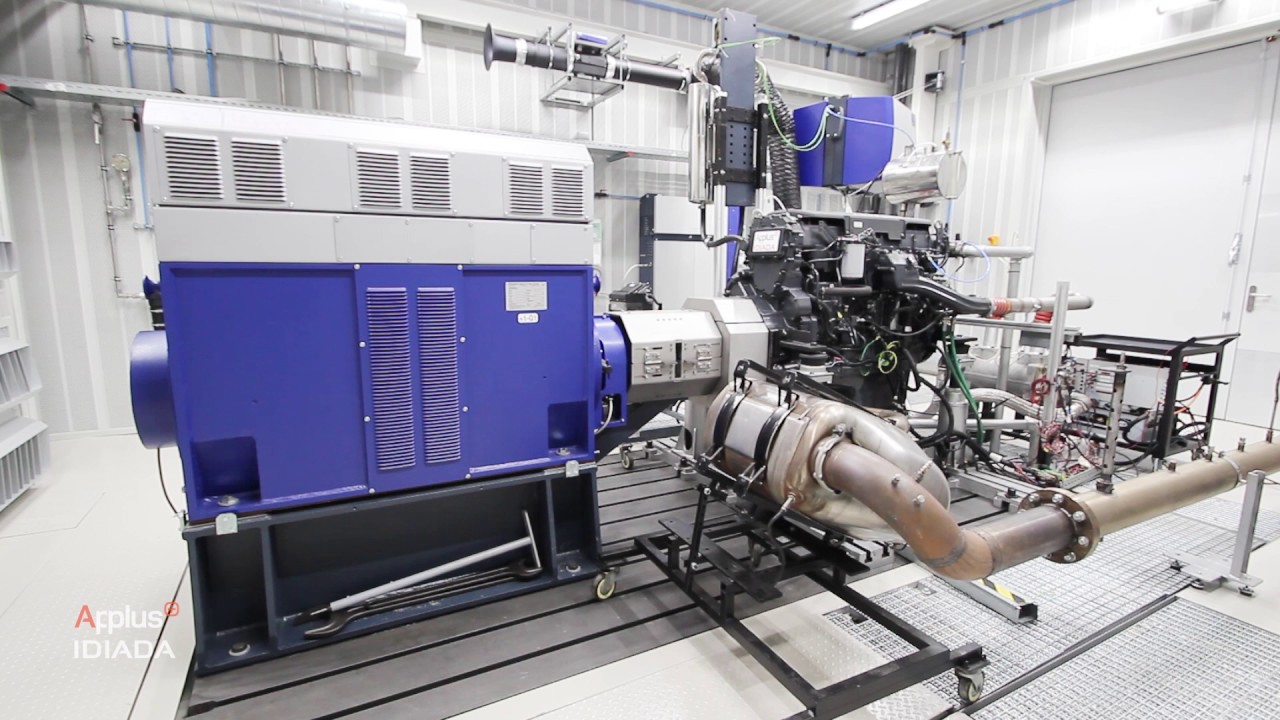

“Cut it twice and again”, which is what many of us have heard. Many of us can use it every day. We all know how difficult it is to keep pulling out the engine, and some of us are afraid of it. When it comes to repairing an automobile engine, you want it to run normally for the first time. It’s OK now! Today we will learn more about the engine test bench and how to help you diagnose problems faster, saving your time and mind.

The engine test bed is a kind of equipment that can be used in the workshop by strange people in the garage or by car technicians. One of these is required to diagnose, adjust, and repair the engine block. The engine test bed is very convenient. If there is no engine test bed, you will never want to do engine projects again. If you are looking at the engine test bed, one test bed can destroy all other test beds with flight marks. Let’s take a look at what makes a high-quality engine test bed today.

High quality engine test bed starts here

The engine test bench is specially made for installing the engine for testing outside the vehicle. For various reasons, the engine test bench is different from other test benches.

Easy access may be one of the highest quality engine test stands you can expect. There is little space to place a bracket that covers engine parts, which may need to be repaired. The unique design provides huge off-site clearance, so the engine test bench can easily diagnose and repair all engine components. Each model has a 54 inch chassis, or 66 inch; in length, there is a cross beam in the middle and a bracket to support the engine block. The radiator, tool holder, control panel and rear mounting system can be easily removed, so they can be removed when not in use, and increase the space for operating the engine.

Safety is another quality that many engine test benches lack, but there is no engine test bench. The fuel tank and battery are separated from each other, one at the front and one at the rear, and the exhaust pipe is left in the longitudinal beam of the frame. In case of emergency, there is a main switch on the instrument panel. The radiator can float up and down to limit cavitation inside the engine. The clock cabinet can be easily removed to check for R/master node and/or O/disk leaks. Most importantly, the stand is stable even when a high-power engine is installed.

Mobility is the reward of engine test bench. The engine test bench is equipped with 6 inches. Casters for easy rotation, sliding under the mounting bracket, working on the engine bracket, and transportation(8 “castor option) It is hoped that in addition to the casters, the engine test bench can also be saved. When not in use, most booths will become dusty rags in the corner of the workshop. This is not the purpose of the engine test stand! Find a bracket that can be easily disassembled with the package when not in use, and keep it until it is reused.